Types of Bag Materials:

What Material Are Bags Made Of

Have you ever been confused by the variety of bag materials when shopping for a bag and didn't know where to start? If you want to learn about what material are bags made of, then you should definitely read this article!

What Material Are Bags Made Of

1. Polyester

Polyester fabric is a kind of chemical fiber fabric and durable materials for bags. Its biggest advantage is that it has good wrinkle resistance. It has high strength and elastic recovery ability. Therefore, it is durable, and ironing-free. Polyester has low moisture absorption, but it is extremely easy to dry after washing and does not deform.

Polyester fabrics are durable materials for bags, but tend to form holes in the presence of sparks. Therefore, try to avoid contact with cigarette butts and sparks.

Polyester fabrics have a good lightfastness(resistance to fading when exposed to light), and its lightfastness is better than natural fiber fabrics. Polyester fabrics have good resistance to various chemicals. Acids and alkalis won't hurt it much, and it is not afraid of molds and insects.

2. Nylon

Nylon is also a type of synthetic fiber and bag materials, its biggest strength is that it is durable and wear-resistant. Nylon fabrics are available in 70D, 210D, 420D and other grades. The larger the number, the stronger the fabric, making it suitable for outdoor bags and other products that require high durability.

In addition to being strong, nylon also has benefits such as lightweight, good elasticity, fatigue resistance, good chemical stability, and resistance to alkalis and acids.

However, nylon bags also have their drawbacks. When exposed to sunlight or UV rays for long periods of time, nylon tends to deteriorate, causing fabrics to become brittle and colors to fade. In terms of price, nylon is generally more expensive than polyester.

3. Canvas

Canvas is a blend of cotton and plant fibers and is usually graded by ounces (oz), which is the weight of the canvas per square yard. The higher the ounces, the thicker, heavier and stronger the canvas. Canvas used for bags generally ranges from 8 to 16 ounces.

Canvas is a very durable material for bags. It can withstand large amounts of weight and has good breathability and moisture absorption. However, this good moisture absorption also means that canvas can be heavy under wet conditions and can dry slowly. For this reason, many canvas products are treated with a waterproofing coating, such as a layer of wax.

4. Oxford

Oxford cloth can be made by nylon or polyester, or a blend of the two.

a. Nylon Oxfords: usually high strength, wear-resistant, lightweight, commonly used in outdoor backpacks, mountaineering bags etc..

b. Polyester Oxfords: Compared to nylon Oxford Fabric, polyester Oxford Fabric has better light and chemical resistance, and is more suitable for long-term outdoor exposure.

c. Blended Oxford Fabrics: combining the advantages of nylon and polyester, it has better wear resistance, strength and durability. They are very good bag materials.

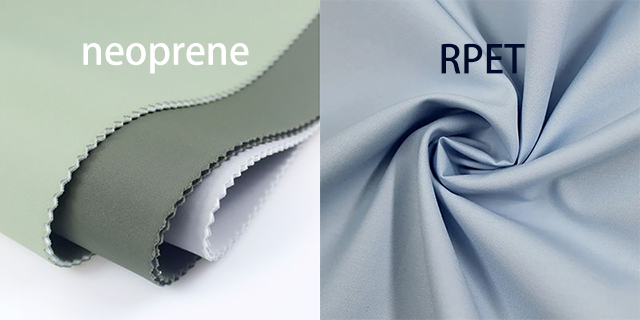

5. Neoprene

Neoprene is a synthetic rubber that is elastic and waterproof. It is often used for bags that require a high level of waterproofing, especially bags that need to maintain a certain shape. Neoprene fabric is thick, soft, durable and has good insulating properties, and also used to make wetsuits.

6. Eco-Friendly Bag Materials

As environmental awareness increases, more and more bag manufacturers are using eco-friendly materials for their bags. These materials are made from recycled plastic, including polyester(RPET), organic cotton, recycled nylon and more.

These materials effectively reduce the footprint on the environment while having similar durability and functionality as traditional fabrics.

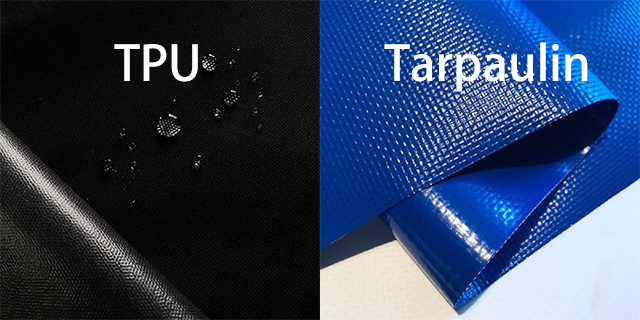

7. TPU and Tarpaulin

TPU and Tarpaulin are commonly used to make waterproof bags and dive bags.The materials are generally joined using High Frequency Welding to ensure that there are no seams at the joints.

a. TPU:

TPU materials have excellent waterproofing, cold and heat resistance and will not brittle or harden under extreme temperatures. Its elasticity is very good, adaptable to bending and stretching, especially suitable for diving equipment that need to be folded frequently.

There are single and double-sided TPU, TPU is classified into single-sided and double-sided. common thicknesses :20mil (0.5mm), 40mil (1mm), etc. TPU materials are usually available in transparent, matte, and color, suitable for different design needs. It's eco-friendly and recyclable, so it's widely used in high-end outdoor backpacks and diving bags.

b. Tarpaulin:

Tarpaulin material is PVC+Mesh+PVC, which is highly worn, tear-resistant and loadable. The double-layer PVC structure ensures strong waterproof performance, which is suitable for dry bags and outdoor bags.

Owing to the relatively heavy PVC material, Tarpaulin bags are more suitable for heavy-duty outdoor use. Through the process of high frequency welding, the Tarpaulin has no stitches at the joints, which also effectively improves the waterproof effect, especially suitable for outdoor equipment in harsh environments.

Non-fabric

In addition to the above mentioned, the bag materials also include leather, which is categorized into artificial leather and real leather.

1. Leather:

Leather is the most classic choice for handbags. Leather bags are usually expensive because of the high cost of the leather material. And it requires regular maintenance to maintain its appearance, avoiding exposure to overly dry or humid environments,scratches, heat and cold,etc.. If not properly cared for, leather may crack, warp or fade. However, if cared for carefully, the leather will become softer and more beautiful over time.

2. Artificial Leather:

Artificial leather is divided into PVC and PU leather. PU leather is better because it is softer and won't split open due to heavy loads. Artificial leather's breathability is weaker than real leather, but it is less expensive, easier to maintain, and usually more hard-wearing than genuine leather.

But compared with fabric, artificial leather is still less wear-resistant, and more sensitive to temperature. It may melt or stick at high temperatures, and become brittle and break at low temperatures.

Over time, artificial leather is likely to fade and wrinkle, the surface coating may flake off, and the appearance will be significantly aged. Not really a type of durable materials for bags.

The Back of Fabrics

The fabrics are rarely used singly. Bag manufacturers often add PU or PVC coating to the fabric to enhance their waterproofness, wear resistance, and durability. Common fabrics with coatings are nylon, polyester, oxford cloth, canvas.

The coating is usually faced inwards, which enhances functionality while maintaining the look and feel of the outer fabric. So PU or PVC coating is often called PU and PVC back. PU and PVC back are very different.

a. PU Back:

Pros: PU back is soft and more flexible than PVC back. PU backs have good breathability, and cold resistance, not easy to flake off in conditions that are too hot or too cold. It's nice and comfortable, and has a long lifespan.

Cons: PU coating has a more complex production process, so it is more expensive than PVC coating.

b. PVC Back:

Pros: PVC back is thick, highly wear-resistant and waterproof. It can withstand harsh conditions, and is cheaper than PU back.

Cons: As PVC is thicker and heavier, it is less breathable. Additionally, it is not resistant to cold and can become hard and brittle in low-temperature environments.

Conclusion

Choosing the right bag materials is key to balancing durability, style, and functionality. Whether it's the ruggedness of canvas, the lightweight of nylon, or the eco-friendliness of recycled fabrics, understanding these materials ensures your bag fits your lifestyle perfectly.

English

English Deutsch

Deutsch español

español